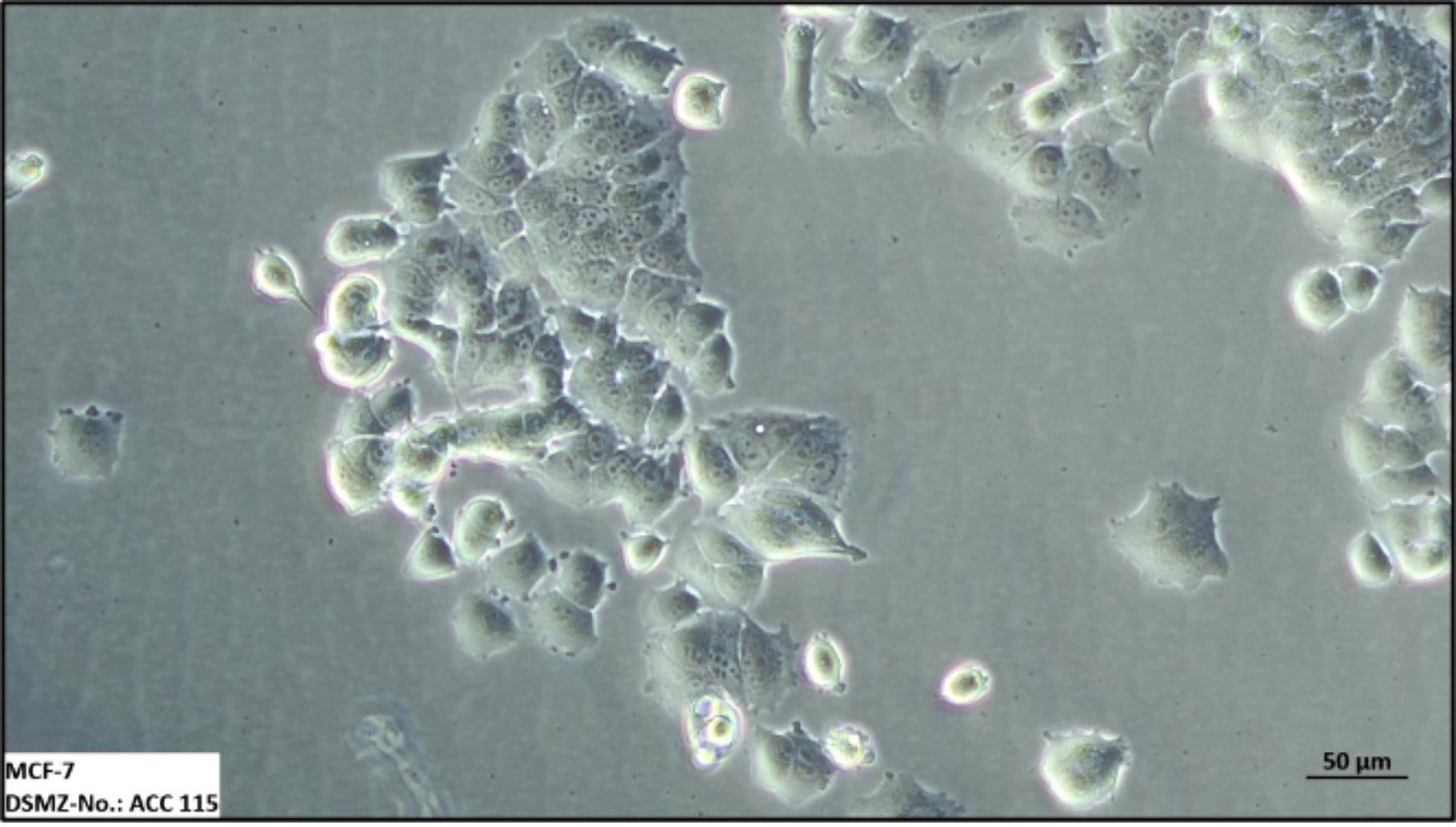

New Global Core Biodata Resources: Four DSMZ Databases

DSMZ is delighted that the importance of its Digital Diversity platform has been underlined by further international recognition of its key databases Four global and three European awards, received by scientific databases developed at the Leibniz Institute DSMZ-German Collection of Microorganisms and Cell Cultures GmbH, underline the recognition of the institute“s new role as an infrastructure for biological data of global scientific importance. The Global Biodata Coalition (GBC) recognises biodata resources that are of fundamental importance to the wider biological and life sciences community and to the long-term preservation of…

Mehr...